Alright, so back in 2022 I started riding bikes again, and to make sure I wasn’t putting a lot of money into something without proof of commitment, I bought a used 2015 Fairdale Coaster from Re-Cycles Bike Shop in Richmond, VA. In a short few months I rode with increasing frequency and distance, eventually hitting my first 20+ mile ride on a single speed bike. Then I was hit by a pickup truck on September 1st, and while I was fine (other than contusions), enough of the bike was wrecked that it sat in storage. I was able to have the frame repaired for a mere $35. For my money, that resilience and repairability are why I choose steel bikes in the city.

Anyway, I’ve held on to the frame with the intention of turning it into a grocery bike with gears. But since it was originally a coaster brake bike with narrow track dropouts, I knew I’d have to modify it. The bike was essentially a write-off; I used the money I was paid by the guy who hit me to buy my Space Horse, so I was only off the road for 5 days after all. If I tried modifying the Fairdale and screwed up, it was no big loss on my end. But I didn’t screw it up! I stripped most of the bike down and then I ran into something weird.

When I pulled off the cranks, I wasn’t looking at the expected BSA square taper. Instead there was a splined shaft and larger, exposed bearings pressed directly into the shell. I did some measurements and while the shell width was 68mm, the inner diameter was just over 41mm. And then I remembered that Fairdale came out of Odyssey BMX, so I started researching BMX bottom bracket standards. Sure, I could have stuck with BMX cranks, but I wanted the flexibility to use a wider range of cranks from my parts bin (or swap in the future), and that meant BSA for me. Was this even possible? Based on my measurements, it became clear that Fairdale used the trickiest BMX bottom bracket standard to convert: mid. Now in the BMX world this would appear to be pretty solid; large bearings for a strong and durable BB. But finding conversion options was nearly impossible. American BB shells have just a large enough inner diameter that there are more options, and Euro is really the same as BSA.

Well it seemed like there was only one company I could find that made a “mid to iso/Euro” conversion kit, and it’s the British company Mafiabikes. I still don’t know a whole lot about them, but I know they had the part I seemed to need and it was $35. But there’s basically no information on the website and hardly anything I could find on the web about using these conversion cups. I’m fortunate enough to be able take a $35 risk, so I placed the order. In the mean time I could have a battle with the old pressed-in bearings, eventually knocking them out with the help of a socket extension, some penetrating oil, and a rubber mallet.

Having thoroughly cleaned the interior of the BB shell, it was time to make all this work.

I basically had 2 threaded cups that should press fit into the shell and I would need to use some Loctite green retention compound to hold it in place. I was lucky enough to already have an old 110mm square taper BB that has at least a little life remaining (for grocery runs at least).

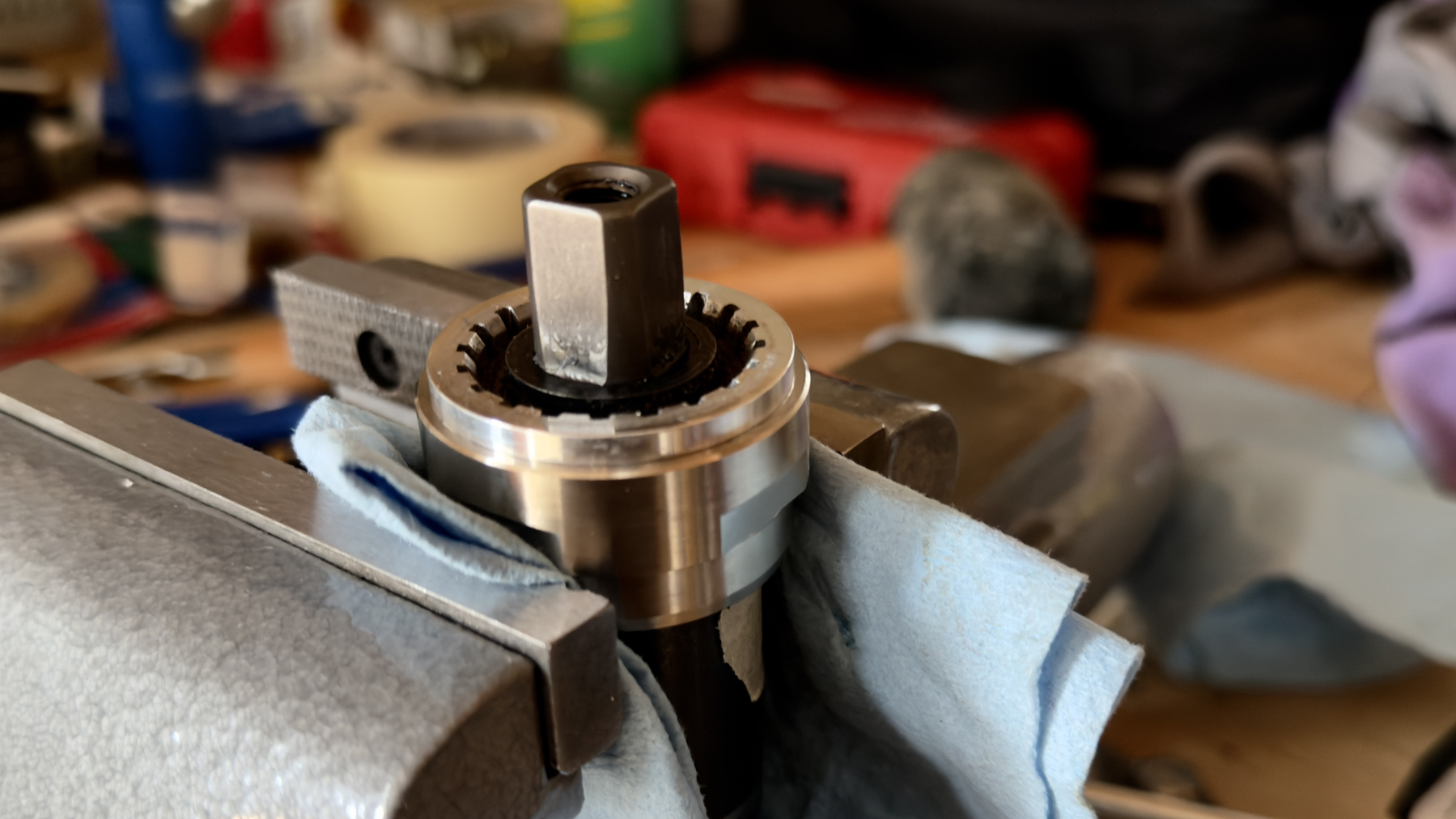

The conversion cups had wrench flats which was helpful for dry-fitting the BB, but I wasn’t quite sure how I would press the threaded-in BB to the shell with the spindle in there, so I just tested the fit first by holding the cups in my vice.

Ultimately I added the Loctite and used my vice (with protective cardboard) to slowly, and carefully press in each conversion cup, one side at a time. It didn’t even take 10 minutes before the Loctite was set enough for me to torque down the drive-side of the BB to 50 N-m. Another major step of this slow conversion/build finished!

I don’t know how many bike shops would even know this is possible, let alone try doing this for you. I have to say I’m fairly proud of my self for figuring all of this out and actually succeeding. It’s also nice to know that with enough patience and willingness to tinker, you can figure out almost anything on a bike.